Innovations

The people and projects that set us apart

Transdermal Alcohol

Fire Pollution Monitoring

Monitoring on the ISS

Air Quality Wearable

Safe Drinking Water

Zero Power Sensor

Methane Mems Sensor

Ozone Sterilization

SPEC Sensors

Low-Power Electrochemical Gas Sensors

Wearable Noninvasive Blood Alcohol Monitor

The goal of this proposed NIH SBIR Phase II program will be to continue development and commercialization of a new noninvasive transdermal alcohol monitor. The monitor will be in wristband or watch form, similar to a smartwatch. This device will be modern, attractive and comfortable and will have smartwatch features including measuring key physiological parameters (e.g., pulse) with wireless communication to apps on smartphones and other devices. The aim of the work is to provide a new, noninvasive transdermal alcohol monitor into the market.

Michael Carter

Director of Research

mcarter@kwjengineering.com

Dr. Carter has been leading the research department at KWJ since 2010, innovating new solutions to gas detection problems, advancing research in gas sensing systems, and serving as a mentor for the research team. Continue Reading

Agency: Department of Health and Human Services

Branch: National Institute of Health

Award: 2R44AA024651-02

Title: Wearable Noninvasive Blood Alcohol Monitor

Amount: $1,334,590.00

Program: SBIR

Year: 2017-2019

Principal Investigator: Michael Carter

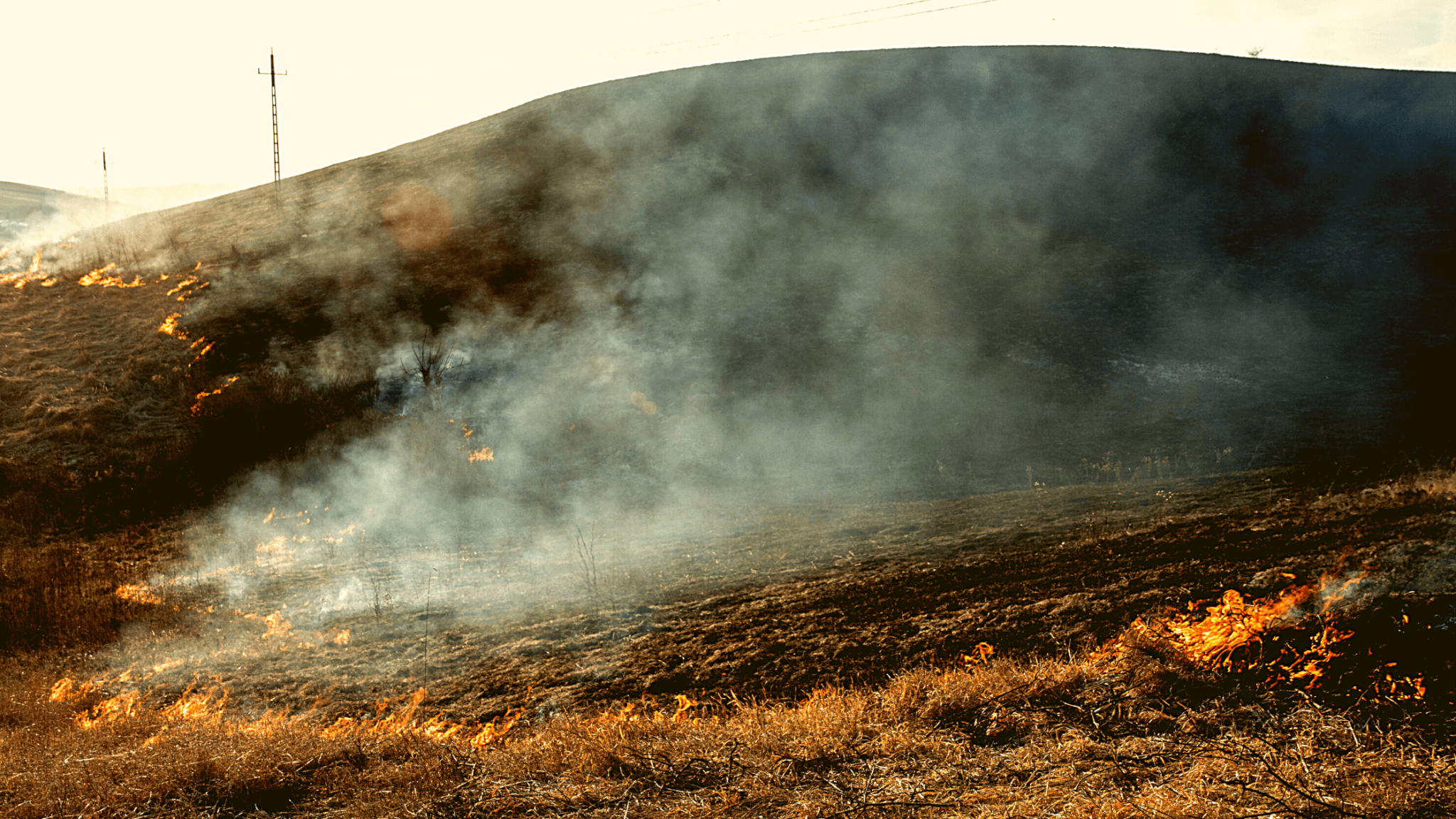

Ground Level Air Pollution Monitoring from Wildland Fires

EPA Grant: Ultralow Power Sensor Package for Ground Level Air Pollution Levels from Wildland Fires

Wild fires produce significant air pollution, posing health risks to first responders, residents in nearby areas, and downwind communities. Wildfires are increasing in size and intensity, and the fire season is growing longer. Technologies for measuring air pollutants, including particulates, carbon monoxide, nitrogen dioxide, and carbon dioxide, over the wide range of levels expected in areas downwind of wildland fires are needed.

KWJ proposes to integrate printed gas sensors and particle sensor into a single, <8oz package.

—

USDA Grant: Ultralow Power Sensors for Firefighter Safety and Monitoring of Surrounding Air Quality

KWJ has developed a line of small, low-cost yet accurate electrochemical gas sensors, with very low-power electronics. KWJ is also working with several collaborators to develop of an ultralow power sensor for monitoring atmospheric “ultrafine” particulate. For particulate, we propose to develop a miniature, extremely low-power electrostatic PM monitor by integrating our patented “diffuse plasma ionization sources” (DPIS) with electrostatic plates for fractionation and measurement of particulate.We plan to integrate the gas and particulate sensors into a single, low-power and lightweight package which can be deployed in distributed networks of stationary as well as wearable/mobile sensor modules.

Mel Findlay

Senior Principle Engineer

R&D, Engineering Services, and Product Development

mfindlay@kwjengineering.com

Mr. Findlay has more than 25 years’ experience in environmental chemistry and analytical methods in air and water, with a focus on the development of portable sensors and instrumentation.

EPA Award: KWJ Engineering, Inc.

Contract Number: 68HERC20C0053

Title: Ultralow Power Sensor Package for Ground Level Air Pollution Levels from Wildland Fires

Amount: $300,000.00

Program: SBIR – Phase II

Year: 2020-2022

Principal Investigator: Mel Findlay

USDA Award: KWJ Engineering, Inc.

Award Number: 2020-33530-32997

Title: Ultralow Power Sensors for Firefighter Safety and Monitoring of Surrounding Air Quality

Amount: $599,896.00

Program: Small Business Grant – Phase II

Year: 2020-2022

Principal Investigator: Mel Findlay

Autonomous Environmental Monitoring and Management Platform for Remote Habitats

Title: Autonomous Environmental Monitoring and Management Platform for Remote Habitats

An automated mobile air quality (AQ) sensor array will provide high quality environmental data within the confined physical parameters of a space habitat. Project results, including generated data, will be used to develop algorithms for artificial intelligence (AI) which will ultimately automate monitoring of experiments as well as life support systems on the International Space Station (ISS), the Lunar Gateway, and beyond.

Initially, SPEC Sensors will demonstrate a platform for AQ monitoring in a form factor compatible with autonomous robots such as the Astrobee, currently in use aboard the ISS National Laboratory. In this phase, ground-based laboratory evaluations will be performed with a mobile prototype to address flight certification requirements necessary for integration with the current Astrobee fleet, and for safe delivery to the ISS National Lab by Magnitude.io. These experiments will also generate the training data for the proposed machine learning algorithms developed by the University of Missouri – St. Louis. The complexity of these algorithms will determine hardware requirements for the final phases of the project. For example, a reference array mounted on a mobile robot, in conjunction with remote fixed arrays will require a unique implementation of edge-computing methods and mesh-compatible hardware.

In Phase II, the platform will perform passive AQ monitoring from the payload bay of an Astrobee during sorties on the ISS. The temporal, spatial, and physical environmental data collected from these flights will generate real training data for machine learning development, and require minimal support from the station’s crew. Finally, in Phase III of this project, with updated software and hardware, this system will be provided to NASA and the ISS National Lab for integration into current and future operational systems. With the successful demonstration of this technology, we expect other needs will arise that can be solved with this AI enabled array.

David Peaslee

Research and Development

KWJ Engineering and SPEC Sensors

dpeaslee@spec-sensors.com

Dr. David Peaslee is a key member of the sensor research and development team for both KWJ Engineering and SPEC Sensors. His research in electrochemical modeling has been pivotal in improving the selectivity and accuracy of SPEC’s electrochemical sensors.

EPA Award: to SPEC Sensors, LLC

Award Number: T4.04-5080

Title: Autonomous Environmental Monitoring and Management Platform for Remote Habitats

Amount: $100,000.00

Program: SBIR-STTR

Year: 2020

Principal Investigator: David Peaslee

Wearable for Environmental Monitoring

Title: Low-Cost Wearable Device for Total Environmental Health Monitoring

The World Health Organization (WHO) is predicting more than 6 million deaths this year and untold injury, making air quality the fourth largest contributor to the human disease burden. Additionally, the USAF has indicated a need for a modular wearable instrument, capable of measuring atmospheric volatiles, aerosols, and pollutants. This will enable real time environmental monitoring of the surroundings that service members are exposed to in the workplace and in the home. This will also provide the necessary understanding to assess the risks associated with Total Exposure Health (TEH). SPEC Sensors plans to leverage its expertise in manufacturing commercial gas sensors, as well as its ability to develop novel methods of sensor miniaturization to create a truly wearable environmental sensing solution, which includes a 12-gas mixed sensor array in an initial form factor of 56 cubic inches. With the development of a stable, highly sensitive aerosol/particle detector, this volume is expected to decrease to less than 10 cubic inches. This reduced volume is possible due to the SPEC Sensors’ compact profile and very low power requirements. This technology will enable the USAF (and the average consumer) to identify potential health hazards and to mitigate risks before serious injury to health

Anticipated Benefits/Potential Commercial Applications

Given the link between the quality of the air we breathe and human health, monitoring the presence of contaminants such as environmental

David Peaslee

Research and Development

KWJ Engineering and SPEC Sensors

dpeaslee@spec-sensors.com

Dr. David Peaslee is a key member of the sensor research and development team for both KWJ Engineering and SPEC Sensors. His research in electrochemical modeling has been pivotal in improving the selectivity and accuracy of SPEC’s electrochemical sensors.

Department of Defense: to SPEC Sensors, LLC

Contract Number: FA8650-17-P-6891

Title: Low-Cost Wearable Device for Total Environmental Health Monitoring

Amount: $149,361.00

Program: Air Force, SBIR – Phase I

Year: 2017

Principal Investigator: David Peaslee

Spec Sensors, LLC

Continue reading about SPEC Sensors, our partner company for air quality and gas detection. →

A Simple Lead Test for Drinking Water Safety

The goal of this program is to demonstrate a simple, low cost home test for lead ion, Pb(II), in drinking water. The US is faced with a deteriorating water service system used by many millions of people. This condition poses a serious public health threat, as illustrated recently by the Flint water crisis, but the problem is widespread and expected to grow. A simple, yet reliable test is needed that can be performed by untrained citizens. The test will provide reliable determination of drinking water Pb(II) compared to the 15 ppb Pb(II) action level. Current home tests are of unverified reliability and often are too expensive for routine use or require sending samples to a lab. Adoption of the new home test will result in significant public health benefits for the nation by facilitating drinking water testing. An electrochemical strip will be developed to perform Pb(II) analysis with simple safe/unsafe result provided to the user.

Michael Carter

Director of Research

mcarter@kwjengineering.com

Dr. Carter has been leading the research department at KWJ since 2010, innovating new solutions to gas detection problems, advancing research in gas sensing systems, and serving as a mentor for the research team. Continue Reading

EPA Award to KWJ Engineering, Inc.

Contract Number: EPD17041

Title: A Simple Lead Test for Drinking Water Safety

Amount: $99,965.00

Program: SBIR – Phase I

Year: 2017-2018

Principal Investigator: Michael Carter

Zero Power Electrochemical Sensors

Title: Zero Power Electrochemical Formaldehyde Sensor with Novel Catalyst for Indoor Air Quality

The EPA has announced the need for a low cost Formaldehyde Sensor to reduce exposure to CH2O in the home. SPEC Sensors, LLC. specializes in sensor development, and production, and is focused on bringing air quality monitoring for safety and health into every home. In collaboration with KWJ Engineering Inc., SPEC has worked to design low power and zero power wireless multi sensor systems capable of collecting and transmitting data. This research will focus on printing and characterizing a low cost amperometric CH2O sensor for ambient level monitoring, while optimizing the stability of the printed electrode, and incorporating it into our digital sensor systems.

David Peaslee

Research and Development

KWJ Engineering and SPEC Sensors

dpeaslee@spec-sensors.com

Dr. David Peaslee is a key member of the sensor research and development team for both KWJ Engineering and SPEC Sensors. His research in electrochemical modeling has been pivotal in improving the selectivity and accuracy of SPEC’s electrochemical sensors.

EPA Award: to SPEC Sensors, LLC

Contract Number: EPD17031

Title: Zero Power Electrochemical Formaldehyde Sensor with Novel Catalyst for Indoor Air Quality

Amount: $99, 926.00

Program: SBIR – Phase I

Year: 2017-2018

Principal Investigator: David Peaslee

MEMS Methane Sensor

Title: Inexpensive Low Power Nano-Sensor Based Measurement of Fugitive Methane Emissions

The proposed EPA SBIR Phase I program will create a novel ultra low power and low cost microfabricated CH4 sensor. The initial developments of sensor technology will serve the EPA mission of identifying fugitive methane emissions, and subsequently the very large methane/ natural gas leak and safety market that has been identified by KWJ and its collaborators. Phase I is dedicated to design, fabrication and testing of the innovative system consisting of a unique MEMS sensor, discreet electronic components and proprietary “smart” algorithm.

Mel Findlay

Senior Principle Engineer

R&D, Engineering Services, and Product Development

mfindlay@kwjengineering.com

Mr. Findlay has more than 25 years’ experience in environmental chemistry and analytical methods in air and water, with a focus on the development of portable sensors and instrumentation.

EPA Award: to KWJ Engineering, Inc.

Contract Number: EPD17034

Title: Inexpensive Low Power Nano-Sensor Based Measurement of Fugitive Methane Emissions

Amount: $99,989.00

Program: SBIR – Phase I

Year: 2017-2018

Principal Investigator: Michael Carter

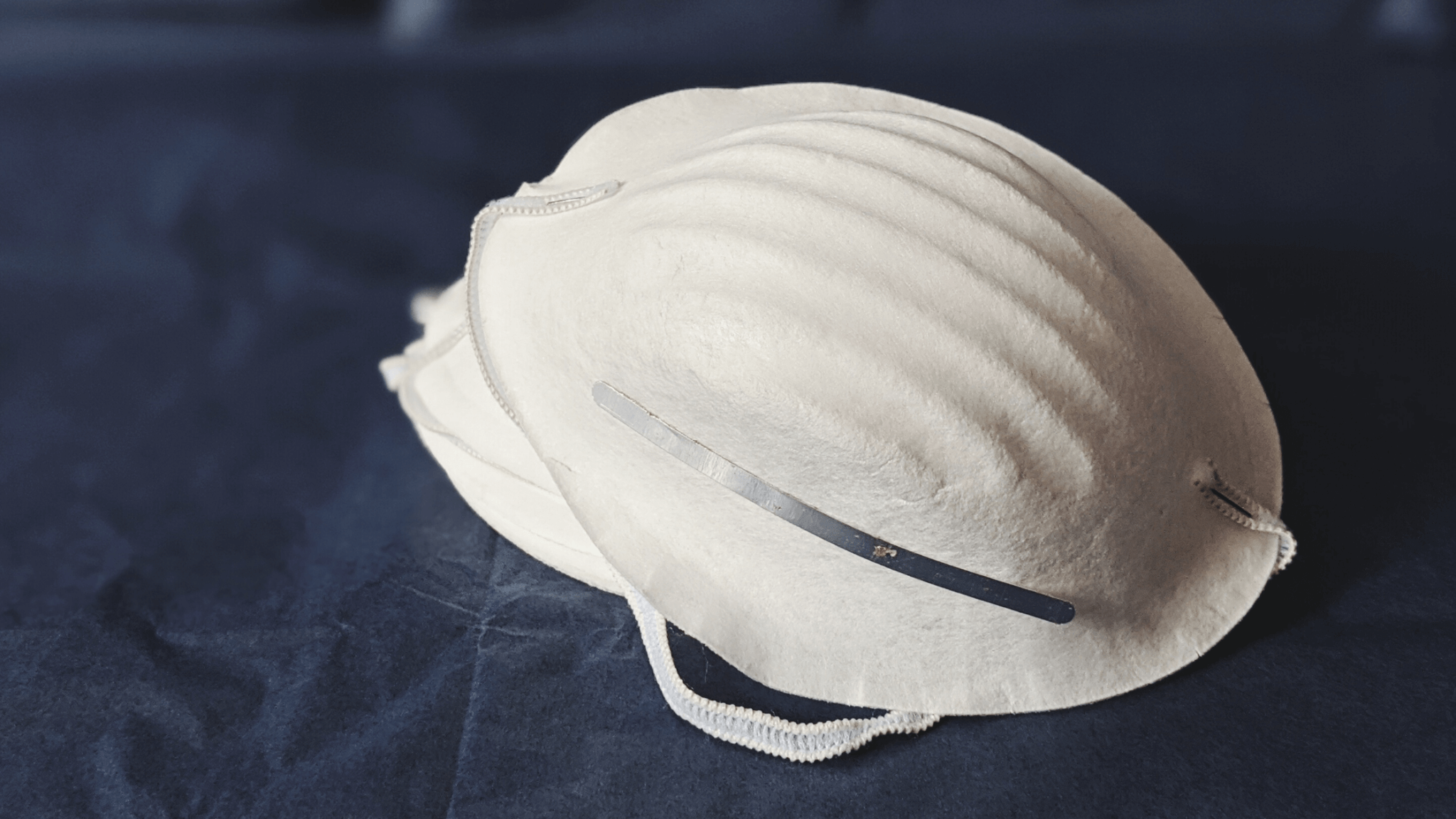

Ozone Sterilization

TITLE: A Small Novel Low-Cost Ozone Sterilizer for COVID-19 Field Use.

Purpose: The integration of several technologies from prior SBIRs in sensor development and ozone sterilization will be combined into a controlled, portable sterilization chamber using ozone exposure to deactivate the SARS-COV-2 virus on N95 facemasks and other equipment.

Innovation: The technical innovation herein is the production and validation of a low-cost, effective sterilizer for personal protective equipment [S4PPE]. We propose a modular sterilizer design which requires no toxic chemical consumables, generates the ozone sterilant as needed to precisely controlled concentrations, and uses common parts made in USA as far as possible. Our team of engineers, with the 100+ years of combined experience in commercial products for ozone sterilization of water and air [ozone sensors and controllers], have performed related SBIRs and have arrived at an innovative design that can be quickly constructed and tested in the field in a matter of weeks. The novel ozone sterilizer is now being demonstrated to be an effective sterilant for bacteria and several viruses the USEPA designates as harder to kill than covid19. The innovative S4PPE has a number of potential advantages over other decontaminating gases and liquid chemical applications: ozone is a natural compound, is easily generated in situ from oxygen or air, and reverts to oxygen – in air – with a half-life of about 20 minutes, leaving no residue, smell or taste. As a gas it can penetrate all areas within the chamber, including crevices, fabrics, and the undersurfaces much more efficiently than UV light, liquid sprays, and aerosols.

contact us for more information

Joseph Stetter

Founder & Chief Technology Officer

KWJ Engineering and SPEC Sensors

JRStetter@KWJengineering.com

For nearly 40 years, Dr. Joseph Stetter has been at the forefront of chemical sensor and associated technology as a leading researcher, entrepreneur, author, and educator.

Title: A Small Novel Low-Cost Sterilizer for COVID-19 Field Use.

Year: 2020

Principal Investigator: Dr. Joseph Stetter

This project is the result of in-house design, research, and product development. Please contact us for more information.

Air Quality Detection with SPEC SENSORS

SPEC Sensors was founded in 2012 and built from the Research and Development of KWJ Engineering, Inc. SPEC Sensors provides low-cost, low-power electrochemical sensors for CO, O3, NO2, SO2, H2S, and Ethanol.

Screen-Printed Technology for High Performance Gas Sensors

Title: Screen-Printed Gas Sensor Using Nanoparticulate Catalyst

This Small Business Innovation Research (SBIR) Phase II project seeks to combine the technology for a high performance amperometric gas sensor, AGS, with the fabrication methods of printed electronics, first for sensing carbon monoxide (CO). In Phase I KWJ demonstrated a unique combination of technologies and fabricated a CO sensor that, in performance testing, was compared to commercial sensors 10-100 times larger and 10-100 times more expensive. The new unique geometry sensor response characteristics we as good or better than commercial sensors. The printed-AGS sensor provides a general platform for sensors that is both low cost and high performance. In Phase II, this novel Printed-CO-sensor and the process for fabrication will be optimized and innovative beta-prototypes designed and fabricated. The prototype sensors will be subjected to comprehensive testing and integrated with state-of-the-art electronics including tiny micro-powered RFID technology to demonstrate a fully compensated, high performance, yet low-cost, CO sensor and sensor system. This would represent the first major advancement of AGS technology in the USA in several decades, and the resulting product is potentially disruptive to the marketplace.

Joseph Stetter

Founder & Chief Technology Officer

KWJ Engineering and SPEC Sensors

JRStetter@KWJengineering.com

For nearly 40 years, Dr. Joseph Stetter has been at the forefront of chemical sensor and associated technology as a leading researcher, entrepreneur, author, and educator.

National Science Foundation award to KWJ Engineering Inc.

Award Number: 1058563

Title: Screen-Printed Gas Sensor Using Nanoparticulate Catalyst

Amount: $1, 357, 293.00

Program: NSF, SBIR – Phase II

Year: 2011

Principal Investigator: Dr. Joseph Stetter

M. T. Carter, J. R. Stetter, M. W. Findlay and V. Patel. “Advanced Electrochemical Gas Sensors Employing Novel Designs and Electrolytes”, 04/15/2012-10/31/2012, 2011, “220th ECS Meeting Boston, MA”.