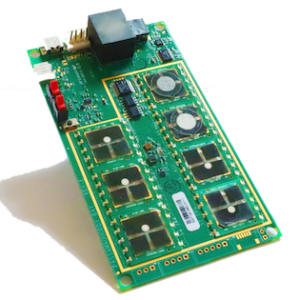

KWJ Engineering uses advanced manufacturing processes to open up new applications for gas sensors to improve health, safety, and efficiency. The device can detect a specific gas, like methane or carbon monoxide, while avoiding false alarms.

KWJ Engineering Inc. Printed Electrochemical Gas Sensors

KWJ Engineering has brought gas sensor manufacturing down to the nanoscale to produce tiny, low powerhigh performance sensors with the goal of embedding sensors in smart phones, smart building systems, textiles, and other technologies.

KWJ began with trusted technologies found in commercial applications – proven, OSHAcompliant, methods for printed electronics to flatten gas sensors to less than a millimeter thick, and to shrink the cost from $150 to less than a few dollars. By reducing the scale of sensors, KWJ has been able to create a versatile device that can detect a specific gas (like methane or carbon monoxide) to alert people of the presence of that gas while avoiding false alarms. They plan to expand the capabilities of the sensors to detect several different gases simultaneously with the same sensor.

There are two sensor platforms: a printed electrochemical sensor (SPEC Sensors) that detects a broad range of gases, including CO, NO2, O2, H2S, ethylene, and ozone, and an ultra-low power MEMS thermal conductivity sensor that can detect methane (for home and infrastructure safety), CO2, and other energy gases that can improve building efficiency. These sensors can also detect things like alcohol on the breath, and even potentially detect diseases and health conditions through breath analysis.

KWJ’s technology will allow new methods for embedding sensors and making those sensors more pervasive and connected for use in everything from health and safety in industrial buildings to personal safety in homes. For example, the sensors could be integrated with first responders’ gear to provide instant detection of invisible dangers. Building managers could receive remote alerts, notifying them of developing leaks or other problems. Integrated into phones, the sensors could provide a method for cities to monitor air quality in real-time as people carry the sensors throughout an area – creating a kind of walking air quality monitor and safety network that spots potential gas leaks, fires, explosive devices, and pockets of poor air quality.

The next generation of gas sensors could also be used to improve demand-controlled ventilation. By measuring CO2, the sensors could be used to estimate the number of people in a room and trigger the ventilation system to turn over the air when needed. They could even be programmed to trigger air handling based on the presence of VOCs, or bad odors. This type of precise control means that energy is not used to recycle a building’s air when it’s not needed.

The first applications of KWJ’s new sensors include a screen-printed CO sensor for on-the-go detection and a Bluetooth-enabled home CO monitor that communicates with a person’s cell phone for remote alerts.

BACKGROUND

http://www.kwjengineering.com/

See the full article here: http://www.dmass.net/nvp/KWJ