Newark, CA – Earlier this year, the Federal Aviation Administration (FAA) released their report Detection and Prevention of Carbon Monoxide Exposure in General Aviation Aircraft. An abstract of the document is as follows: “Exposure to carbon monoxide (CO), which is formed by the incomplete combustion of carbon-containing materials such as aviation fuels, is associated with headache, dizziness, fatigue, and at elevated doses, death. Exhaust system failures in general aviation (GA) aircraft can result in CO exposure. When this occurs in an aircraft, the end result could be an accident. This research on detection and prevention of CO exposure in GA aircraft addressed the following objectives: (1) to identify protocols to quickly alert users to the presence of excessive CO in the cabin and (2) to evaluate inspection methods and maintenance practices with respect to CO generation. These objectives were accomplished by review of (1) the National Transportation Safety Board database for CO-related incidents/accidents, (2) current CO detector technology, and (3) industry inspection and maintenance practices, Advisory Circulars, and FAA regulations with respect to GA exhaust systems.” (DOT/FAA/AR-09/49)

For this report, the FAA researched the 71,712 cases in the NTSB accident/incident database, and found that 62 cases were directly related to CO exposure. The SDR database, which contains maintenance records of aircraft being serviced from 1995 to the present was searched using keywords related to exhaust systems such as “muffler,” “heat exchanger,” and “heater shroud.” That search resulted in approximately 400 reported cases.

The FAA report also stated, “The FAA standard for CO in an aircraft cabin is no more than 50 ppm [3]; however, there is currently no requirement to monitor for CO in the cabin. Due to the colorless and odorless characteristics of CO, it is extremely difficult to determine if hazardous levels of CO are in the cabin without some type of CO detector technology. However, little guidance exists regarding suitable CO detector technology for use in GA aircraft. Additionally, if CO detectors are used in the cabin of GA aircraft, no guidance exists to recommend the best placement to detect CO quickly and accurately.” (DOT/FAA/AR-09/49)

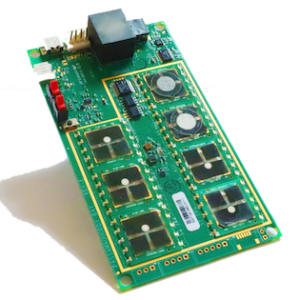

KWJ Engineering, in response to the above statement, presents the Pocket CO. The most affordable and convenient way for every pilot to be protected from carbon monoxide exposure wherever they fly. Â

Pocket CO, designed and built in the USA by KWJ Engineering Inc, is the world’s smallest renewable carbon monoxide detector. Its advanced technology, tiny size, and ease of use, make it perfectly suited for many applications and activities where CO levels should be monitored. In addition to keeping users safe from immediately dangerous levels of CO, Pocket CO also allows monitoring of lower CO levels, which pose long-term exposure heath risks, and collects information, which can be downloaded to any computer using the SmartPocketä Reader, such as maximum and average readings over time.

Pocket CO is already in use by many pilots across the country, but KWJ Engineering, Inc. President and Chief Technical Officer Dr. Joseph Stetter believes too few pilots are actively protecting themselves from exposure to CO.

“It’s about safety and convenience,” Dr. Stetter said, “with the Pocket CO, there is no reason why any pilot should go unprotected from exposure to CO. Even a small amount inside the cabin can affect a pilot’s ability to fly, not to mention the long term health risks associated with repeated, low level exposure. The investment is small, but the returns are priceless…keeping yourself and your passengers safe, happy, and healthy.”

Pocket CO is available from many online aircraft supply retail outlets, as well as directly through KWJ Engineering. For more information about the Pocket CO, and about CO exposure, visit www.detectcarbonmonoxide.com.

KWJ Engineering has been an industry leading provider of cutting edge sensor and instrument solutions for gas detection needs since 1993. Founded by Ken Johnson, an industry pioneer for over 60 years, and headed by Dr. Joseph Stetter, a world recognized sensor expert, KWJ Engineering offers products that meet most any industrial or consumer application. The Pocket CO Model 300 is the third generation of this popular instrument, and bridges the gap between industrial users and every-day consumers. See www.kwjengineering.com for more information and to contact KWJ Engineering.